Testing, Testing

July 19th, 2020 Posted by Bouke Becker Boards, Sails, Tips and motivation No Comment yetTesting, Testing

Testing is off course essential for the development of equipment. First of all you need to go out sailing to get new ideas. And these new ideas will also have to be tested properly before they are sold to customers. But there can be big differences how, what, where and who does the testing.

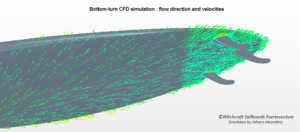

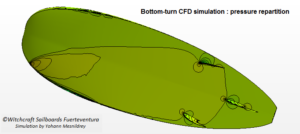

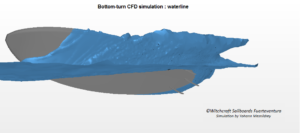

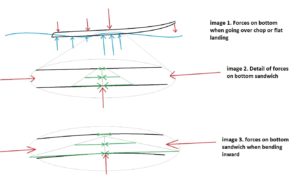

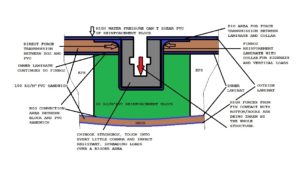

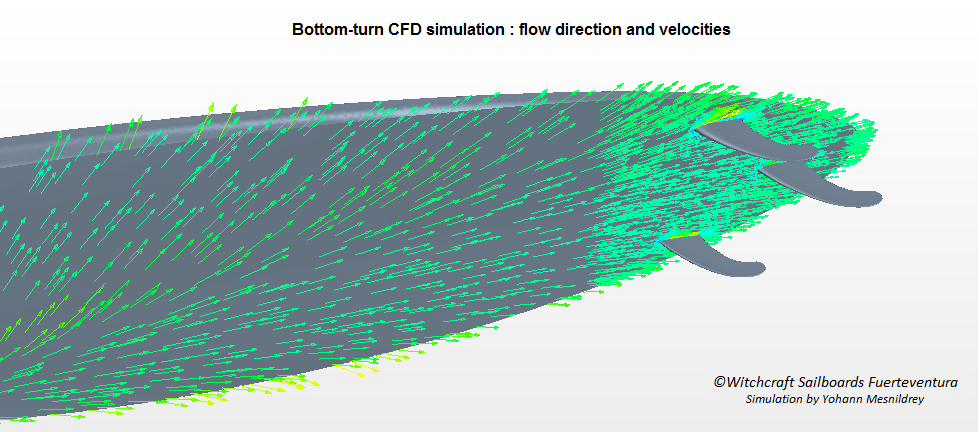

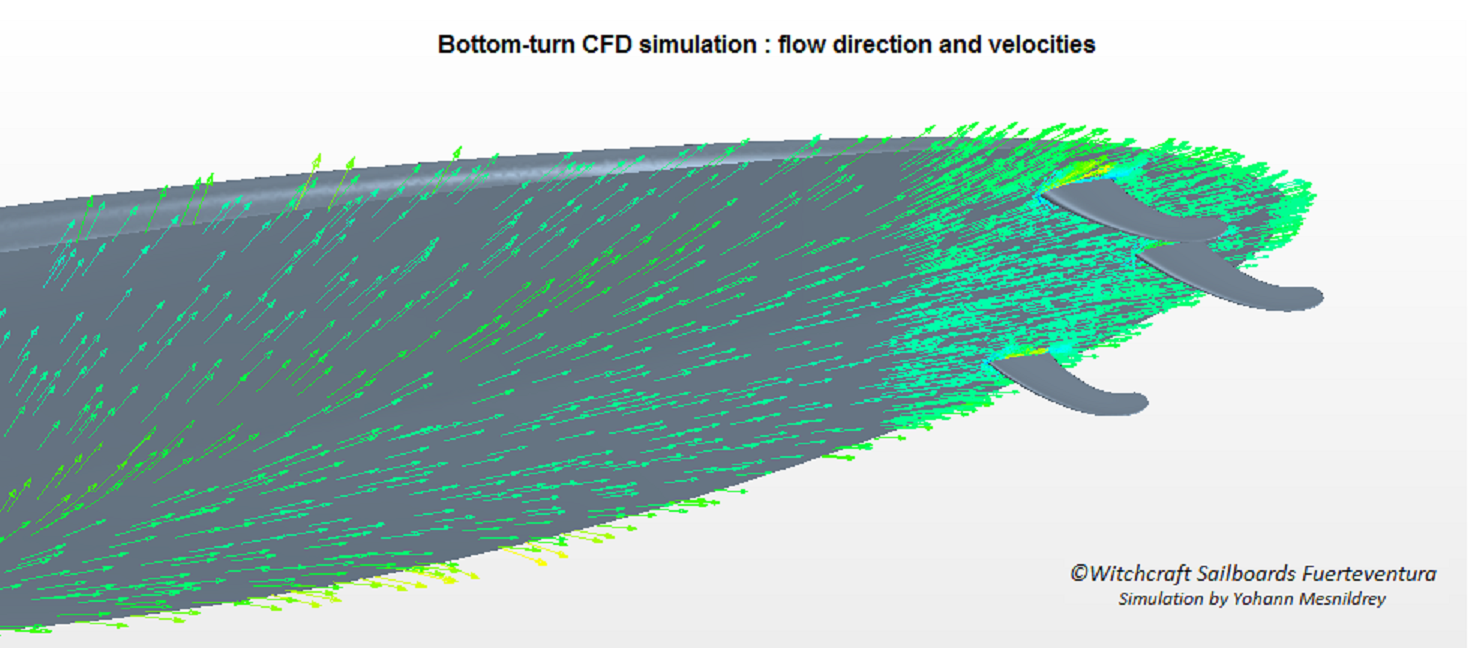

For testing new products, you have various stages. Many products can be tested in laboratory conditions, which give the best and very accurate comparisons. Testing in windsurfing can be very difficult as the conditions we encounter are always changing. Having laboratory like conditions are very useful, especially for testing new designs. The use of CFD (Computer Fluid Dynamics) have indeed given us this possibility. By simulating various critical situations in wave sailing, we can learn a lot about board lift and drag and fin lift and drag. Results come much quicker and far more accurate than you could ever realise even after years of testing in reality. CFD does not only give you lots of data on lift and drag of the board and each individual fin but it can also recommend what to improve. Still, despite all these possibilities, CFD is hardly used in windsurfing, only for slalom fins or foils, which are much easier as the effect of the board or water surface is not taken into account. We at Witchcraft have taken into account the effects of the water surface, the effects that a board is partly in water, partly in air and the effects of the board to the water flow underneath. We have also been filming under water to compare the flow with the CFD results.

As far as I know, no other brand has done anything like this ever. None of the bigger brands with a much bigger budget. Anyone who has tried our fins know that it certainly has paid off.

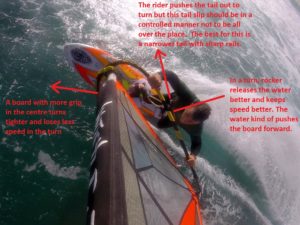

Then having laboratory like real life conditions is very useful to double check the CFD results. For stuff like lift, drag, grip, tight turning, keeping speed, the best is to have clean light wind conditions in such conditions a good sailor who is pushing, feels even small changes. The North Shore of Fuerteventura is known for its clean and predictable waves and at times perfect float n ride conditions unlike pretty much any location in the world. For this kind of testing it is also important to have very skilled riders who can reproduce the same turns over and over again and feel very well what the equipment is doing.

And for each comparison, it is essential to be changing just one parameter at a time. You hear sometimes riders say: “I tested fins with toe-in but they did not work”. So I said, these fins, did they just have toe-in or also have an asymmetrical profile? “Both.” So how do you know it is the toe-in or the asymmetrical profile? Any hydrodynamic expert can tell you that when you change the asymmetry of a fin profile this has an influence on the angle of attack and you need to add more toe-in than for a symmetrical fin. CFD also shows this. There is a lot more going on below a wave board than what you´d think. You even see surf fin manufacturers and/or universities, who spend a good bit of cash on research, testing just the fin in a water tunnel, without a board attached, thus not taking the effects of the board to the water flow underneath into account, so straight away you can throw all your results in the bin as the fin will behave differently when mounted under a board. Quite essential I´d say.

After this kind of important exploring research, you get into the more real world testing. A big argument by the “big” (big is relative these days) brands and their customers is always that their products are tested by pros and in the PWA. But is this really representative for end users? Pros who sail all over the world usually there where it is windy in that period and who have a far bigger quiver than most end users. Boards for on shore or side shore, for light, medium and strong wind, for jumping or riding. Sometimes even light boards for competing.

If boards, developed by pros, were so thoroughly tested, should they not look a lot more similar? How often have we not seen new models appearing on the market with a lot of hype but then being discounted by 50% after 6 months and disappear the next year?

The Formula 1 circus is a big comercial circus in a way. But there are things they do which eventually have benefitted the every day cars you can buy. By giving penalties for each time a team needs to change an engine or other parts, they force competitors to become more durable, by limiting the amount of fuel to be used they improve environmentally friendlier engines.

So if the PWA would take an example from F1, and, for example, allow for a 3 month period to experiment with a variety of equipment but then during the whole competition season put a maximum of say 2 boards and 5 sails to be used, both for competing and training. Then, like in F1, if a board change is wanted or needed, this would cost the rider points, then it would be a lot more similar to how end users use their equipment. This would give a great boost to development which would actually be beneficial for end users: more durable, environmentally friendly equipment with a bigger range.

Now that there is no PWA this year, I get the impression more people are starting to see there is more than the PWA and the brands involved.

I would say this would be a good opportunity to reset the PWA, to change these rules for the benefit of the future. And such a set up would certainly be a lot more interesting for Witchcraft to join in. But I doubt they will even consider this. The PWA is more a marketing tool for them than a way to actually improve development.

In Slalom sailing, is the end user a fully muscle packed pro, who sails full power with a heartbeat of 180 just for 10 mins? Sailing just down wind legs of a few hundred of meters and each time having to jibe and accelerate again? No, far from that. But with the pros being forced to use production equipment, equipment ends up being tuned for the pros and not the end user. Nowadays with GPS any sailor can compare their speed with others on the beach, swap boards and try again.

Another problem such brands face is the delay in feedback from end users. The usual process is that a new shape needs to be handed in by the end of December. After that, moulds are made and first samples are made to be tested. Then when everything is approved, production needs to start to be able to deliver new models in shops in August. From then, the first end users (often national team riders or fan boys) who bought them only have a short time left to deliver feedback and let that flow into the new models. This period is far too short for any thoroughly testing. Magazine tests will usually not appear till spring and in the end do not count. No matters what magazines say in their tests (if they say anything meaningfull at all), it is the end user that counts.

Custom brands usually have a much more direct contact with their customers. Especially if they are based in locations with a high frequency and wide variety of conditions, there will be locals with a high skill level as well as with a medium or lower skill levels but who just love to windsurf. And the shaper and workers at the factory will also be able to test their own creations frequently. And these locations will have many locals who especially moved there to live for windsurfing. And will be a known windsurfing holiday destination where visitors also provide feedback, even if it were just to see how other equipment works and lasts. Frequently having to do repairs on other brands stuff can also be informative, even if it is just to see what doesn´t work……

But you also see custom factories appearing in places far from frequent and a variety of conditions. With all respect but if you are a keen windsurfer and an ambitious shaper or sailmaker, would you not want to move to a location where you can test frequently in a wide variety of conditions? One of the benefits of the EU is to be able to move materials and people to such locations. But you still can´t transport good windsurf conditions elsewhere…..even less to the middle of Europe.

And it simply is a lot more fun too to live somewhere like that rather than being stuck somewhere hours away from some infrequent mediocre conditions. And without being able to test frequently and thoroughly, development can only happen at a fraction of the speed. With the only other option left is to try to copy what you can but this means you will always be running behind without even really having a clue whether it is good or bad what you are trying to copy. It would not be the first time that brands, desperate for something new, go the wrong way and others still follow. In recent years Stubbies or 3 batten sails come to mind.

And basically all these things count for sails as well.

Witchcraft moved from Terschelling, a dutch North Sea island (not that bad at all for windsurfing) to Fuerteventura in 1993, simply to windsurf a lot more frequently in better conditions.

Terschelling 1987:

Here on Fuerte we have a wide variety of all kinds of conditions, right in our back yard and a good variety of local riders, including the people making the equipment, getting a lot of added and

direct feedback. We regularly have clean laboratory like conditions but also choppy waves, long soft waves, hollow waves, on shore waves, off shore waves, close out waves, Jaws like conditions, flat water or B&J. We have light winds and high winds plus added conditions at Sotavento, Lanzarote or Pozo. We have shallow waters, rocks, sand and UV light attacking equipment during sailing and rigging. Material wears down 4 times faster here so you know lots faster what is good or not. All this forced us to quickly improve loads right from the beginning and has continued to do so over all these years.

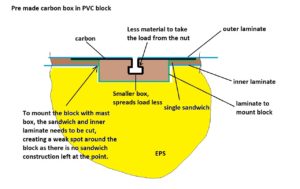

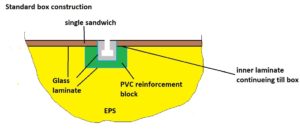

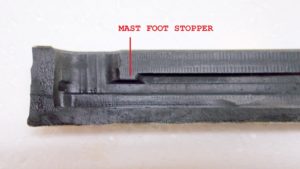

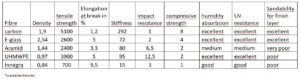

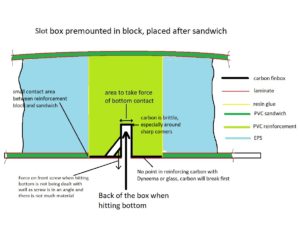

I am sure that even a small thing like the slot box would not have made it into production if it had been tested by the locals here. Various have tried to set up business here but only lasted a few years and in the end couldn´t even sell their stuff for 1/3rd of the price. And for sure not materials like Carbon-Kevlar or even more stupid constructions like putting thin Dyneema over carbon. Even if your engineering skills lack and can´t figure out before hand why this is a bad idea, after one time being washed on the rocks and having to repair it yourself, would have made it clear it´s a worse solution than plain glass fibre at a fraction of the cost and it would never have ended up with an amount of customers who were told they bought something strong “as it has Dyneema”.

You´ll struggle to find any location on earth offering such a variety of conditions within a short drive and amount of sailable days over a year’s time. Locations where up wind ability and early planing is very important to get on a wave first but then, once on the wave, turnability, control and keeping speed is also very important. This has also led to the development of our pre-twisted fins and the flex tail.

Our working hours and the short drive allow us to sail every single day there are conditions, which, with foiling and surfing included, is at least 300 days per year if you want to.

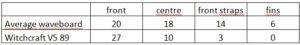

Then we also get feedback from an international team of riders of different levels. And sailing in different locations along the coasts of most European countries and travelling abroad. Using just one or 2 boards and one set of sails, just like most end users.

Plus, as we have direct contact with most of our customers, they also provide us with valuable feedback, they can contact us directly with any problem, question, suggestion or simply say how happy they are. In the end, a happy customer is the best promotion.

And maybe you may still think, well I do not sail that frequently in such demanding conditions. Well first of all, if you do not have such frequent conditions, any windy day is even more valuable and any day lost can´t be made up for, ever. Secondly having better developed equipment with a wider range simply gives more fun on the water. Thirdly having more durable equipment pays of in the long run, it has a higher resale value if you want to renovate, it allows you to plan equipment renovations better and you will not be forced to buy something quickly that is less value for your money and may not be exactly that what you were looking for. And last but certainly not least, it is better for the environment.