Unique Aramid frame panel lay out

Tested in heavy shorebreaks!

Overlapping panel reinforcements at clew and tack

Overlapping batten pockets

The battenpockets are made by overlapping the panel below and above to both sides of the batten pocket rather than joining the panels with a single seam in the middle and slapping the batten pocket on top. This gives a double seam and a fully symmetrical profile. Both seams are double stitched.

Double seams

Double ring clew

Use both rings for the average position.

This is also stronger for if there is a heavy shorebreak.

The top ring can be used for light wind+taller sailors,

the lower ring for high wind+short sailors.

A BIT OF SAIL THEORY

There are a few basic guidelines for sails (or any foil really):

-a sail converts wind into power by bending the airflow. So the more bend, the more power.

-The lee side of a foil delivers 2/3rd of the power. So important to keep the lee side smooth.

-The first 1/3rd of a foil delivers 2/3rd of the power. Or better said: mast length is more important than boomlength or surface.

Wave sails can get shape either through batten rotation or seam shaping.

-Batten rotation:

Pro: Depowering and less drag down the line

Contra: smaller windrange

Batten rotation allows the sail to become flat without wind so the sail can depower when needed. But, as battens them selves want to stay straight, such sails require more wind to power up. Also the stability of the sail then relies only on batten profiling, with a reduced top end control as a result. When set full, a rotational sail can be hard to rotate and become even more unstable, also the mast pocket does not line up with the sail well anymore, losing efficiency.

-Seam shaping:

Pro: big wind range

Contra: depowering and drag down the line

Seam shape pre-bends the battens and has more low end power as the wind does not need to bend the battens to get shape. Also the stability does not only rely on the batten profile but also by the shape of the sail itself with a higher top end as a result. As the shape is always there, the battens are derotated all the time, the sail does not depower well and drags more when going down the line. When set flatter, a sail with only seam shaping has the batten tips not lining up with the mast pocket, creating a bump on the leeward side creating a loss of power. Sail rotation is also harder and power delivery more jerky.

Witchcraft sails are designed to use a combination of both seam shaping and batten rotation to create the best of both worlds:

-There is good low end power as the battens are halfway pre-bent.

-As the battens them selves want to become straight, the sail still depowers very well.

-As the profile stability is held by both seam shaping and batten profiling there is a very good top end control, even when set full.

-As the mast pocket lines up with the sail at all times, there is increased efficiency and soft batten rotation throughout the settings range.

-The higher aspect ratio also makes the sail more efficient for its surface. Therefore you can rig a smaller and lighter sail with a shorter boom giving more manoeuvrability and liberty to move the sail more and faster in turns.

THE PROFILE DEPTH MORPHS THROUGH THE RANGE, THE SMALLER THE SIZE THE LESS SEAM SHAPE AND THE MORE BATTEN ROTATION.

In this way a smaller biggest sail can be chosen. Not only does being able to use a smaller sail save weight but also gives you a stronger rig. The smaller the sail the less loading a wave can put on the sail and a smaller sail exerts less leverage on your mast and boom, it’s a win win situation.

In higher winds, you don´t want to have to use a too small a sail either so with each size down, the profile is reduced a bit. So the total wind range that a typical sail range of 3.7-4.2-4.7-5.2 covers, is bigger than with sails that are all cut the same.

CLEW

In the clew there are 2 eyelets offering more tuning options. Using both eyelets (see rigging manual) will give the average setting. Use the lower eyelet for more loose leach (powered up blasting, B&J, cross off shore wave riding) or the top eyelet for a tighter leach for cross on shore riding, where you have to bottom turn going clew first.

THE CONSTRUCTION IS ABOUT THE BEST POSSIBLE

We are experienced sail makers with many years of repairing sails. There is lots of Kevlar X-ply and all panels are layed out into the forcelines, similar to membrane sails but less cost intensive, much more puncture resistant and easier to repair if necessary. The batten pockets are made with overlapping panels, creating a symmetrical sail shape and giving a double seam for extra strength without costing extra weight.

All important seams are double and running along the stress lines and are not put across stress lines for optical reasons. Like this the seams actually work as tendons. Also at the clew and tack, the joining panels widen again to overlap and create the reinforcement by the panels itself rather than needing all reinforcements being stuck on.

We chose our own seam tape with very strong and durable adhesion and does not suffer from contact with water or UV light.

MOST IMPORTANT STAND OUT FEATURES:

-Overlapping symmetrical batten pockets

-Forceline orientated panel lay out with Kevlar UD In the most important stress lines

-Repair friendly

-Double seams where needed

-Seams serve as tendons

-Overlapping panels at clew and tack

-Panels are thicker where needed and lighter where possible

-Strong seam tape that does not deteriorate by water or sunlight

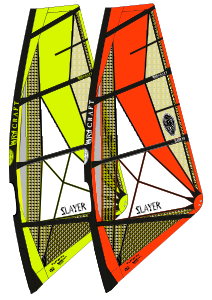

-The Slayer also features a Dyneema mast sleeve which is 10 times more cut resistant and 40% lighter

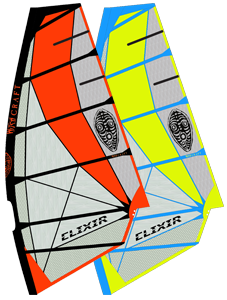

There is an overlap between the Slayer and the Karma but also some differences:

The Slayer is better for:

-For side to side off shore conditions

-Lighter wind wave riding (when the wave provides more speed and the apparent wind in the sail is less)

-More vertical wave riding (clew is higher and the sail depowers better)

-Lighter riders (if you are lighter, the Slayer is works well for powered up sailing as well)

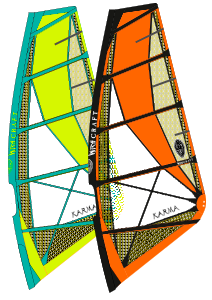

The Karma is better for:

-For side to on shore conditions

-Powered up wave riding (when you need more windpower to keep speed)

-Jumping, Blasting, B&J

-Heavier riders (if you are heavy, the Karma works well for light wind wave riding as well)

Some may choose the Karma for their bigger wave sails and the Slayer for the smaller sizes but also the other way around can make sense if you mainly sail higher winds at home and travel to lighter wind DTL locations.

Both sails are excellent foil sails, experts have said better than dedicated foil sails.