With WC’s Bouke Becker possessing a wealth of shaping experience – having made custom windsurf boards for many sailors over the years – we thought we should revisit this topic for our latest article and see where custom’s at in 2019.

Why do you think custom windsurf boards never took quite as much a hold as they did (traditionally) in surfing?

I think the main reason is that a good windsurf board in sandwich construction is much harder to make. The needed techniques are also much harder to learn. Where surfboards with a blank and a simple glass polyester laminate without any vacuum bagging is pretty simple to learn and does not cost much of an investment in tools and materials either.

What does a custom windsurf board offer over a production type?

Anything really. We already have a very extensive range of semi-custom boards with 68 Wave, Freewave and Freestyle models in 3 different constructions. But still there can be many reasons to go custom. Volume, shape, construction or graphics can all be adapted or chosen individually to the Liter and to the mm. With any board, the possibilities and combinations are endless so it is not so hard to find a reason to go custom. If you can´t decide between an 86 or 90L as it needs to fit between an 80 and 96 I can make it an 88L.

Describe the process (in brief) of how you order a custom Witchcraft windsurf board?

On the website there is a shape inquiry form: https://witchcraft.nu/boards/custom/shape-inquiry/

Here you can fill out the obvious details I will need such as your weight, length and shoe size. Also which sails will be used on the board, where the board will be used and what level you are. Then you will need to describe what you expect from the board, preferably in comparison with known boards and I will need all info about your sailing that you can give me. Which boards you have sailed and which boards you will keep in the quiver or not.

How do you, as the designer, interpret the wants and needs of a sailor looking to go custom?

If the customer has specific wishes I will need to dig deeper to find out more. It is always hard to describe performance in words so we need some points which we both know. You have different meanings of a ‘fast’ wave board; early planing, fast upwind, high top speed, fast on a wave, and then on a sloppy wave or a powerful wave. Good control in a straight line requires quite a different shape than good control on a wave. So the best way to know where a customer is coming from is to know which boards she/he is used to, which boards she/he has tried and what she/he liked and didn´t like about all these. I keep track of the shapes of most boards out there for this reason and if I don´t know a board I will need to find out. Also pictures or video are very useful to know someone’s stance, where does someone have the boom, harness line length, foot strap position and so on. I have to know all about your windsurfing. I have had customers saying: My family got bigger so I can only take one board in our motor home but the board will be used in 14 to 35 knots, from a lake to side shore conditions on the Atlantic coast, with sails from 3.7 to 6.0. They realise that compromises will have to be made but we´ll have to figure out where to place the compromise. This can take quite a bit of discussion. What´s more important for someone, what´s most frequent, etc. Keeping a session log book can be very useful for this as we tend to look back through rose tinted glasses.

You also have customers saying: I am looking for a light wind wave board on top of my default wave board, or to go between 2 given boards, that is usually straighter forward. Also of course for regular customers it is usually easier.

A misconception some people have is to think that when they order a custom they have to tell me what shape it needs to become. A customer needs to tell me what they expect the board to do and then I decide on the shape. They may have ideas on width, volume and such, which is fine but even that has to be seen in relation to the whole shape and where these indications come from. Some custom shapers will offer various rocker lines to choose from. But this is actually the most difficult to assess. Leaving this up to the customer is bad practice in my opinion. It is easy to put the responsibility in their hands where I think this should be the shaper’s job.

Do you usually nail it first time?

Usually, yes. Though I have got it wrong as well. For example: I had someone who has a Wave V3 and asked for the same board but bigger for lighter winds but since he sails mainly onshore conditions and likes to jump, I convinced him he would be better off with a Haka ST type of shape. He liked it a lot but not as much as his V3 so I replaced it for a V3 as that was what he asked for in the first place.

Another customer had an older small single fin custom with lots of rocker from a brand that had stopped and he wanted a fast board to replace it. He was mainly sailing onshore conditions so I made him a board with less rocker but after a few sessions he said it was slower. Even if this seems contradictive, the customer is always right. We had both lacked a bit in our discussions, he had failed to point out that he actually found his high rockered board fast and I had presumed too quick that a flatter rockered board would be the right thing for him. So I made him another board with more rocker with us both paying half of the difference and he was very happy then.

I do give guarantees on the shape of custom boards that it will the best they can find providing I have been given the correct and full info and the customer has been putting an effort in as well to make it work for him.

Sometimes seemingly little things such as foot strap positions can make a world of difference. But if all else fails, I will make a new board till it is right. I learn a lot from these things too so I see it as learning costs. And it is not that the old board is worthless all of a sudden, most of the time there will be someone else whom it suits.

Does custom allow for experimentation with new products, shapes and ideas?

I’d rather keep the experiments limited to prototypes or customs for team riders. You can go a bit out of the box sometimes, for example when a heavier customer asks for a bigger board that was not made before in that size but in 10L less worked well. By making customs for all different kinds of people and conditions, I have learned how to scale boards for different riders but similar conditions. In my program, I can scale in different ways to accommodate for lighter winds or heavier sailors, either need a different way of scaling.

Recently I made a slalom board for someone. It´s been many years that I made a slalom board so I said I wasn´t sure it would be 100% but he said that even 95% would be good enough as he was going through too many slalom boards. So I gave it my best, we had lots of discussions about the different shapes and the partly very choppy conditions he sails in. Also Witchcraft co-sail designer John Blackwell of sailrepair.co.uk has sailed many slalom boards and he also had some valuable input. So by being able to adapt the shape to this with more V and slightly bigger cutouts, it actually ended up being better than the boards he had before. Luckily as I had to follow my instincts rather than knowing for sure.

How much longer does it take to get a custom Witchcraft windsurf board?

That depends on the waiting list. As our semi-custom range is very extensive, far more than any of the big brands, we don´t have a stock and each board is made after ordering. Just that the shapes and graphics are fixed and they are made inside the EU, the prices are lower and include shipping. For both the semi-custom range or a full custom the waiting list can vary between 1 and 4 months, on average it is 2-3 months.

Anything else you’d add regarding custom Witchcraft windsurf boards?

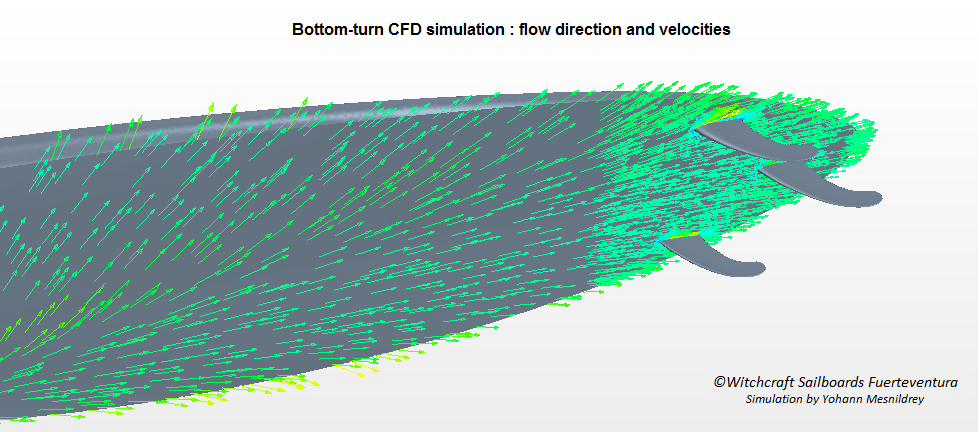

Apart from the shape also the constructions offer the best durability/weight ratio what is possible with today’s materials. I like to work with student interns to do research and we´ve done various computer simulation programs on the strength and hydrodynamics of boards. Then of course we also test everything in practice to the maximum, for which we are in a very good location here on Fuerteventura. I have paid lots of learning money in the early years due to the heavy conditions we can find here for sailors who will take risks and the frequency and variety of conditions. Even if customers would want to pay double, there is very little that could be improved. Over the 25 years I am based here I have improved the repairability of the boards by choosing an intelligent layup from inside out and by choosing paints and graphics that are easy to touch up.

I am keeping a constant eye out for any developments on the composite front. There are some improvements but often not useable for windsurfing. Fireproof materials for example is not really a requirement. I have been experimenting with resin mixed with nanocarbon. But it makes the resin stiffer so it delaminates earlier with Dyneema. I choose my resin to its toughness with a touch lower modulus so the Dyneema takes the most impact. It is very easy to look up the different properties of the different materials on the internet. For example, glass fibre is twice as impact resistant than carbon. Or if you put 2 layers of fabric on top of each other and you turn the 2nd layer 45°, it becomes 15% stronger. Without adding weight. And there are many many more example of such “magic tricks”. It´s not really magic off course, it is logical to use of mechanical properties, physical laws and science and many many sessions of testing over more than 25 years. And with each damage looking if it could have been prevented or limited.

Where it is not possible to make an environmentally friendly board, but, due to the durability, I think I can safely say that our boards are the least harmful for the environment. Whenever I buy something myself, I rather spend more, usually it will not only last longer thus making up for the extra costs but it will also work better.