Our back yard is the North Shore of Fuerteventura where, within a 10 minute drive from our R&D centre, we can find many world class wave sailing conditions. We have spent over 25 years of testing in some of the toughest conditions you can find, repairing damaged boards and developed composites engineering techniques to perfect our constructions. When you have demanding conditions at your door step you get to see frequently what works and what doesn´t and learn a multiple times faster than in locations without good conditions. Throughout our boards you can find intelligent but still very logical solutions, using the specific qualities of the various materials there where they are needed most.

One example are our fin boxes. Experience shows that the biggest forces on a fin box is when hitting bottom. And experience tells us that sooner or later prtty much anyone will hit the bottom with their fins. When we started using multifins we thought we can sail in shallower waters and still hit the bottom.

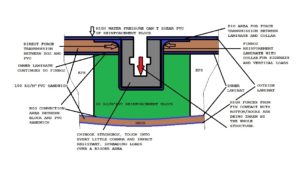

The best way to place a fin box is to first place the reinforcement block together with the sandwich so there is a big connection area between block and sandwich with laminate in between. This even saves time. Also the harder sandwich sheet then sits directly against the box without the slightly softer reinforcement block in between. After the reinforcement blocks and bottom sandwich, the cavities for the boxes are milled by CNC, this saves a lot of measuring time and is accurate to the 0.1mm and 0.1° of toe-in angle.

The Chinook Strongbox US box we use is made of very tough plastic reinforced with a high percentage of glass fibre. Glass fibre is twice as strong against impact as carbon and the high pressure injection moulding technique used ensures the fibres are in every corner and the automated production process is failure free. The thicker walls of the Chinook Strong box also provides a bigger area to take the impact from hitting the bottom. We mount the boxes with various layers of high grade glass fibre which is then smoothly guided over into the bottom sandwich for the best load distribution.

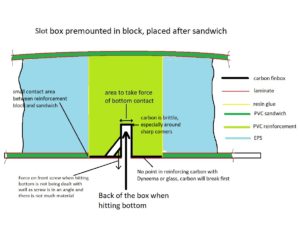

As a comparison here is also a carbon slot box, pre moulded into the reinforcement block before mounting into the board. The box needs to be placed after the sandwich, for which the hole cut into the sandwich needs to be a lot bigger. The carbon box is lighter but carbon is also very brittle and does not handle impact well. Carbon is especiall brittle where it is making a sharp corner. Reinforcing with Dyneema or glass is pointless, as carbon is a lot stiffer, it will take all the force and the glass or Dyneema will not do anything until the carbon is already broken. Also the weight saving is done by using a thinner wall, causing the area to take the vertical load from hitting the bottom to be much smaller. The screws of slot boxes are also not ideal to take the load from hitting the bottom. The angle is far from ideal plus there is little material to stop the screw from breaking out.

Then you also get the more products from factories aimed at bigger quantities which often do not work as accurately. This can lead to production mistakes likes this where the fin box and reinforcement block are more or less floating inside the reinforcement block. This is likely to break easily when hitting the bottom but it may be hard to get guarantee after hitting the bottom, if you are still within the guarantee period at all.