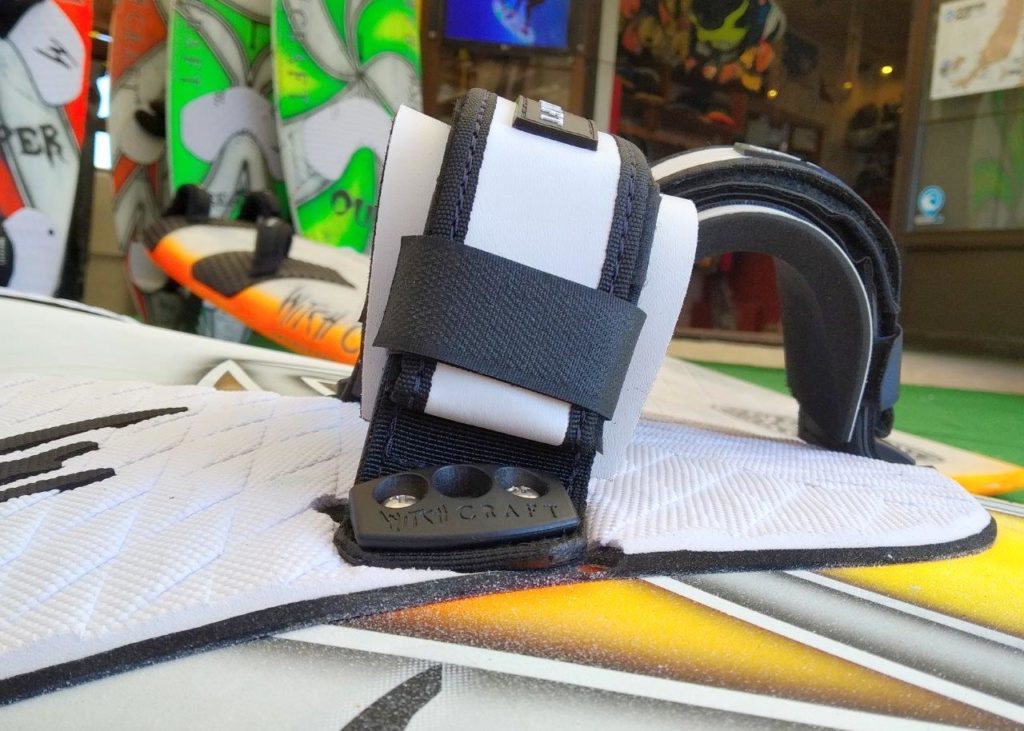

The straps supplied can be mounted both symmetrical for the back strap and asymmetrical for the front straps. Mount them with the velcro end pointing backwards to avoid the possibility of water flow lifting the velcro. The screws supplied are stainless steel 4.8mm to 5mm x 25mm long. Use a philips P2 screw driver.

The back strap is mounted symmetrical. Each strap is mounted with 4 screws and 2 plates. The screw heads are sunk into the plates to avoid injuries.

The front straps are mounted asymmetrical so the step inside is higher and the toe side lower to ergonomically adapt to the shape of the foot. This is done by moving the screws which are towards the centre of the board, to the off set hole.

Make sure the straps is screwed down fully tight on the board, the pad has to be squashed down.

Here you can see how the front straps now are angled with the shape of the foot.

The straps can be set very big or very small.

For flying, the straps do not have to be unscrewed, they can simply be taken apart and the velcro parts folded flat on the deck.

The straps can be set very big or very small.

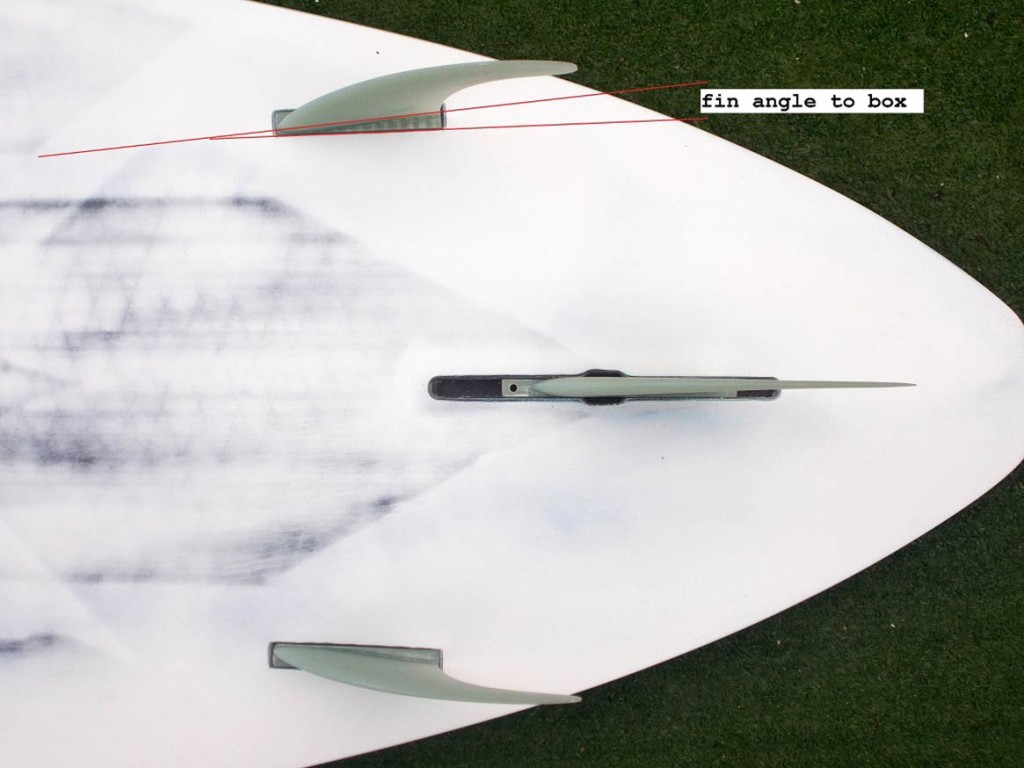

The side fins are pre twisted asymmetrical fins, the logo goes on the outside. Here a picture with how it should look like:

The screws for the side fins are stainless steel M6x30mm. Use a philips P3 screw driver.

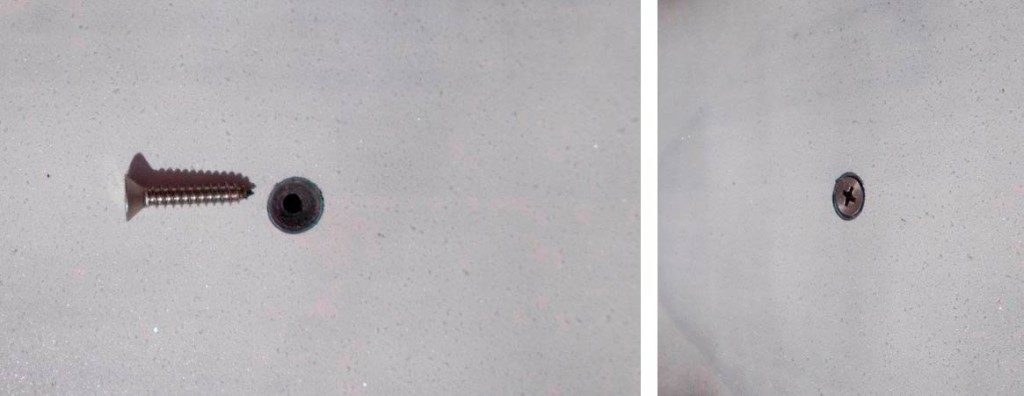

The airvalve is the 4.8x25mm counter sunk screw.

It does not need a rubber ring to close, due to the conical shape of the head it seals off by itself.

Use a philips P2 screw driver.

The screw is a standard DIN 7982 A2 4,8×25 screw which is widely available.

Check further below for instructions on how to operate the valve.

GENERAL MAINTENANCE

No special maintenance is necessary other than regularly checking condition, (check for soft spots, inserts, weight, cracks, spots with dried salt) and proper functioning of the board and its components.

- In case of damage due to impact

Dings can be locally heated out due to the fact that the sandwich material used has memory at a temperature of +/-80°C, use a hairdryer, hot water or a hot air gun (caution: delaminating may occur at temperatures over 100°C) and take your time to let the heat pass through the laminate into the sandwich material. Deeper dents may not disappear completely, cosmetically they can be repaired with body filler and paint. Make sure that a deeper ding does not weaken the construction. - Strong Impacts

On stronger impacts the thin finish layer of carbon or glass fibre, covering the Dyneema cloth, may crack. Apart from some real extreme cases, the Dyneema cloth underneath is very unlikely to break but to prevent water intake through any hair cracks there may be we strongly advice to seal it off with some superglue/cyan-acrylate. This is very liquid and goes into any hair crack there may be, is the quickest drying, transparent and no problem for a proper repair later on. Like this you can keep on sailing till there is time to properly repair the broken glass fibre. Damages of the carbon could lead to a structural weak point and should be checked and if in doubt ask Witchcraft with pictures before sailing. - Ask us

If there are any doubts whatsoever, always feel free to contact us for information however a diagnosis by distance may not be fully correct and no claims can be made in the case of wrong advice.

It is the customers responsibility to operate the airvalve according to the conditions, the valve should be opened only when flying and at temperatures over 50°C.

It is not recommended to open the valve each time after sailing. It is only meant to be opened in extreme situations. The boards are laminated in a special way which avoids air inclosures between laminate and sandwich foam and as such the risk of delamination from air pressure differences (like when flying) alone is very small. However heat over 70°-80C softens PVC and epoxy and this can cause severe damage. So temperatures over 70°C should be avoided at all times, even with the airvalve open. Do not put the board in the sun out of the wind and do not use board bags with a dark side to the sun.

Please also check: Guarantee conditions