Our back yard is the North Shore of Fuerteventura where, within a 10 minute drive from our R&D centre, we can find many world class wave sailing conditions. We have spent over 25 years of testing in some of the toughest conditions you can find, repairing damaged boards and developed composites engineering techniques to perfect our constructions. When you have demanding conditions at your door step you get to see frequently what works and what doesn´t and learn a multiple times faster than in locations without such conditions. Throughout our boards you can find intelligent but still very logical and practical solutions, using the specific qualities of the various materials there where they are needed most.

Witchcraft is famous for the “bulletproof” HDD (Heavy Duty Dyneema®) constructions. Not in the least because of this video: The Witchcraft Hammertest. Also visitors to our rental centre and custom board factory on Fuerteventura can do these tests themselves and many already have.

Dyneema® is also known as UHMWPE or Spectra. We have been working with the fibre since 1994 and know all the do´s and don´ts of this high performance fibre. Till today there is no stronger fibre.

Here some images of boards that were battered on rocks without any hole:

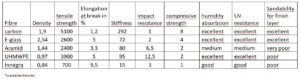

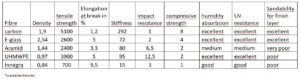

Dyneema has some very good properties such as tensile and impact strength but also not so good properties such as compressive strength, sandability or bonding to resin. Over the years we have found ways to solve these problems and still come out with a better board. We have tried various high tech treatment methods till we found the right one and have our Dyneema specially made to our specifications. Another trick is to use each material there where their properties are most needed.

Dyneema has some very good properties such as tensile and impact strength but also not so good properties such as compressive strength, sandability or bonding to resin. Over the years we have found ways to solve these problems and still come out with a better board. We have tried various high tech treatment methods till we found the right one and have our Dyneema specially made to our specifications. Another trick is to use each material there where their properties are most needed.

See comparison table of properties*.

Since the properties of Innegra are far worse, we do not use it. But also Aramid (Kevlar, Twaron) does not bring any advantage over Dyneema so we don´t use that either.

Since the properties of Innegra are far worse, we do not use it. But also Aramid (Kevlar, Twaron) does not bring any advantage over Dyneema so we don´t use that either.

Stiffness

Now what is very important when combining different fibres is to compare stiffness and elongation at break of each fibre. The stiffer the material the more force it will take. When you want to combine materials, the stiffness should be as similar as possible so the co-operate OR you take care the stiffer material alone is strong enough. For this reason a material like carbon-kevlar is pointless. You think you have the best of both worlds but in the end you only have 50% of each. The carbon will take the most force but there is only 50% of it. When that breaks there is only 50% kevlar left and even if that wouldn´t break, the board still needs a repair which is very difficult with the carbon and kevlar woven into each other. When you have a block of concrete of 100kg and a steel cable that can lift 90kg, what will happen if you add an elastic that can also lift 90kg? First the steel will break and then the elastic. Had you used either steel or elastic that can pull 100kg by itself, things would have been fine. For this reason simple glass is just as good as carbon-kevlar but lots cheaper and easier to use and repair. Carbon-Kevlar (or carbon-Dyneema or carbon-Innegra) only serves marketing, you think you buy something high tech and durable when in fact you do not.

Here is also a nice explanatory video on the subject: Why you SHOULDN’T wrap Fiberglass in Carbon Fiber!

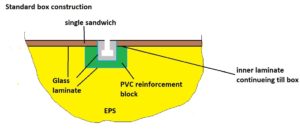

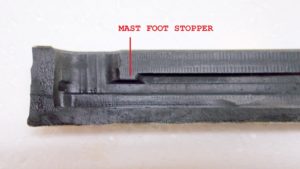

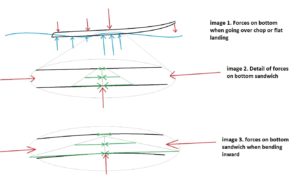

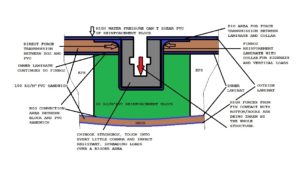

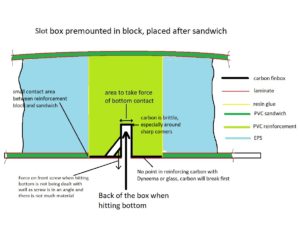

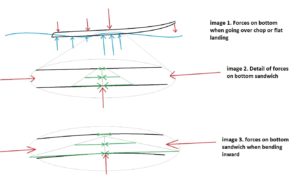

So what we do is to use a full laminate of Dyneema, both on the deck and the bottom, overlapping on the rails. To be able to finish the board, the Dyneema needs to be covered with carbon or glass. As glass has a much more similar stiffness to Dyneema and is twice as impact resistant as carbon we use glass. The main part of the problem of the lower compressive strength of Dyneema is solved in a secret way. And then on top of that we reinforce the areas that are under high compression loads with carbon. The bottom is especially under high compressive load when landing flat. See image below of the forces on the bottom of a slalom board in chop (image 1). The forces when landing flat with a wave board are similar but higher. The bottom sandwich is compressed from the front and back and the water pushes up. As long as the bottom sandwich stays stiff and does not flex, the forces are spread more equally (image 2). The more the sandwich can flex inward, the less favourable the situation gets and the load on the outer layer increases quickly. (image 3)

Hence the main cause for breaking a board is when the bottom can flex inward and finally the outside laminate creases. Carbon UD is the best material to resist compression and creasing.

With carbon we are always taking care that WHERE we use carbon, we use ENOUGH to take the whole load and that where it stops we make the transition very gradual, to avoid sudden differences in stiffness which create weak spots when the whole board is flexing like upon flat landings. Like this the high impact areas such as the nose and rails are just Dyneema or double Dyneema covered with glass. Carbon is the worst material for impact. Also keeping carbon away from these areas means we still allow for some flex in the board, absorbing peak loads. As the saying goes: What bends doesn´t break. If you look well, you can see the carbon UD on the deck and bottom on this board below. The deck does not need much as a compression load is rare and lower.

Repairability

In the whole of the board construction we always think of repairability as well. No matter how impact resistant a board can be, rocks are harder. Since a board made out of rock would be slightly on the heavy side, we have to live with the fact that damages still can occur but we try to limit the damage and make it easy to repair by keeping the damage superficial as much as possible.

Where carbon is needed for its higher compressive strength, it is placed on the outside so that if it damages, it is easily repairable. The Dyneema underneath will still prevent further damage inside. Delamination of Dyneema can occur as the available resins today are simply not as strong as Dyneema. However delamination is easily repaired by injecting a bit of resin with a bit of heat to make the resin more liquid.

We use a sandwich material that is especially for dynamic loads and has memory, between 80°C and 100°C it comes back into its old shape, allowing for dents to be heated out.

The nose is also made with Dyneema under the sandwich and 6 layers of high grade glass fibre to prevent impact damage of the mast. Some people seem to think that if you can hit a board with a hammer, it should also resist a catapult on the nose. However a rig weighs +7kg with a lot of leverage when hitting the nose and a good RDM mast has 4mm thick pre-preg carbon with a round shape. The impact between mast and nose can become so big that something has to give. Either the nose or the mast. Take your pick. If the mast breaks you will have to swim back and the damage is far more costly as masts can´t be repaired and usually leads to damage of the sail as well.

The result: The Witchcraft HDD construction is the best construction for wave boards money can buy. It can´t technically be improved, even if you would want to pay double. And this also means it is the best for the environment and your wallet.

Dyneema is not always Dyneema.

As Dyneema has gotten a very good reputation for impact resistance we also see other brands using it now but often in such a way it completely misses the point. We had one board in for repair with various holes from small impacts which had visibly a full but thin carbon BIAX laminate on the deck and bottom. But the owner said it was Dyneema and he was wondering why it got holes so easily. It turned out it did indeed have a layer of Dyneema covering the carbon but it was very thin, about 1/3rd of what we use. Dyneema is not rubber, any impact will get passed on to the carbon 1:1. With the hard and brittle carbon underneath, this thin Dyneema still could not absorb the little impacts and got punctured. Also in places where it wasn´t punctured but had received compression dents of the mast, the thin carbon underneath had broken, which could not be repaired without removing the covering Dyneema over a bigger area, which then can´t be repaired again because of its poor sandability.

In such a lay up, the use of Dyneema is actually making things worse, it would have been better without Dyneema. Just with carbon it would have been as strong but lighter, cheaper, easier to make and easier to repair. Or even having it made with simple glass fibre would have been more impact resistant, with the same weight, as strong, lots cheaper, easier to make and easier to repair.

So if you see a board that says Dyneema but looks like it has full carbon, don´t buy it. Even if we have spent 20+ years to give Dyneema the reputation it has today, if used by inexperienced people in the wrong way, the outcome may actually be worse. Dyneema is not always Dyneema.